Schweißelektrode GRAU-EB-4.0X450mm -5.0 kg

Description

OVERING TYPE – basic with iron powder

| AWS A 5.1:E 7018 | ISO 2560-А-E 42 4 В 42 Н 5 |

PURPOSE AND FIELD OF APPLICATION

Electrodes “GRAU-EB” designed for welding of critical structures and pipelines made of carbon and low alloy steel with tensile strength from 500 MPa to 640 MPa, especially if high hot cracks resistance of welding joints is needed. Are widely used in bridge building, shipbuilding, ship repairing and tanks production. Welding can be performed in all positions.

APPLICATION CONDITIONS

Deposition rate factor – 10,5-11,5 g/А.hr. Electrode consumption per 1kg of deposited metal is 1,58 kg. Nominal capacity to 115%. Electrodes from 2 mm to 4 mm diameter designed for welding in all spatial positions except vertical down, 5 mm diameter electrodes – for horizontal flat, vertical flat, and vertical up positions.

CHEMICAL COMPOSITION OF DEPOSITED METAL, %

| Mn | Si | C | P | S |

| 1,10-1,50 | 0,40-0,70 | n. e. | ||

| 0,09 | 0,030 | 0,020 | ||

MECHANICAL PROPERTIES OF WELD METAL

| Tensile strenght, N/mm2 | Elongation, % | Impact strength J/cm2 |

| 500-640 | ≥26 | ≥180 |

SPECIAL PROPERTIES

Welding electrodes GRAU-EB are characterized by high strength of metal seam, with special metallurgical purity and low content of hydrogen in welded metal. The possibility of welding on alternating current eliminates the effect of magnetic arc blow. Blobby transfer during welding with GRAU-EB provides better stability of arc combustion and metal seam formation. Due to the addition of iron powder in the electrode coating, the efficiency of using GRAU-EB increased by 20%, while:

- spatter and burning losses of metal are compensated;

- electrodes consumption reduced by 10-15%.

- productivity of surfacing increased by 8-10 %.

- slag does not flow into the molten pool, forming smooth weld seam thereby slag is can be easily removed.

PACKING DATA

| Diameter, mm | Length, mm | Number of electrodes in package, pc | Package weight, kg |

| 2,50 | 350 | – | 2,3 |

| 3,20 | 350 | – | 2,3 |

| 4,00 | 450 | 71-74 | 5 |

| 5,00 | 450 | 47-50 | 5 |

EQUIVALENTS

| Producers | Electrode classification |

| ESAB | OK 48.00, OK 48.05 |

| Lincoln Electric | Basic One |

| ELGA | P48S |

BAKING BEFORE WELDING

At the normal storage conditions, the electrode baking is not required. In case of moisture the baking is made at 110±10°С for 25-30 min.

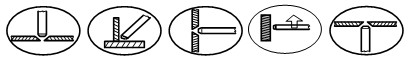

WELDING POSITIONS

PA PB PC PF PE EN 287

Certification